Member Introduction: Care4Living – Cancer Drugs and Antibiotics with Microbes

- Aug 5, 2025

- 2 min read

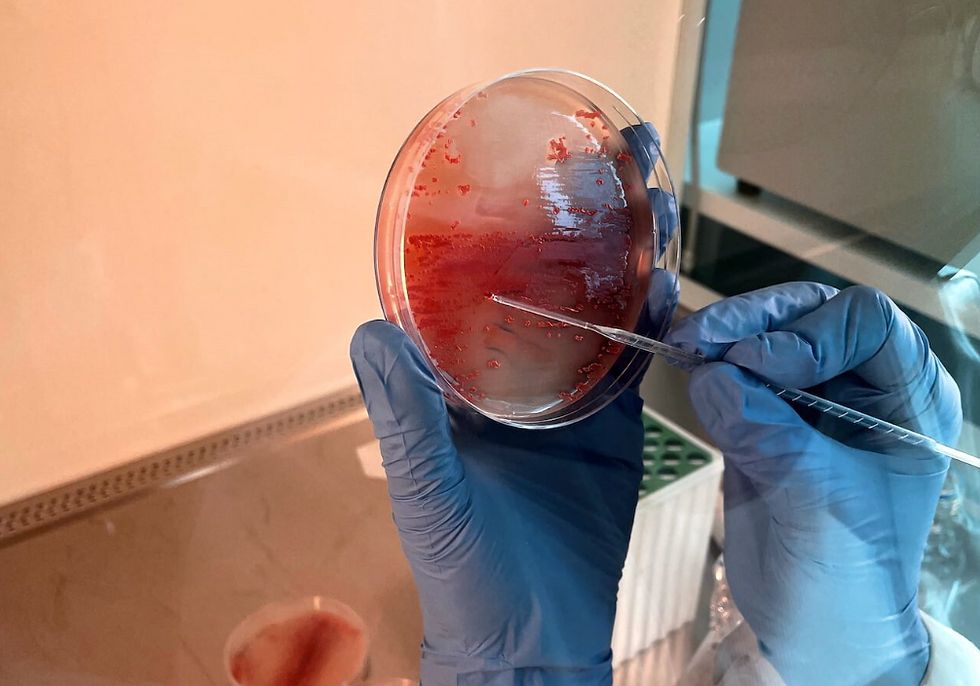

Care4Living Oy is a Turku-based biotechnology company focused on fermentation-based drug substances. The company uses microbial processes—typically involving bacteria—to produce active pharmaceutical ingredients in bioreactors. Care4Living develops microbial strain-based production processes for its clients to manufacture products such as antibiotics, cancer drugs, and immunosuppressive compounds.

The company was founded by Kristiina Ylihonko, who has worked with microbes in the pharmaceutical industry since the 1980s. Care4Living has been operating for over a decade and employs a team of seven. Its laboratory is located in the Werstas facility in Turku’s Pharma City.

“Our expertise lies in letting the bacteria do the work—not the chemists,” Ylihonko says. “We use microbes to produce drug substances because they can carry out synthesis that would be chemically extremely difficult or even impossible. For example, producing one API (Active Pharmaceutical Ingredient) for cancer drug through full chemical synthesis would require over 40 reaction steps, while fermentation reduces that to four.”

Care4Living’s main workhorse is the bacterial genus Streptomyces, considered one of the most important natural sources of pharmaceuticals. A single Streptomyces strain can potentially produce dozens of biologically active compounds—various antibiotics, cytotoxic substances, and other secondary metabolites. However, many of these compounds are not produced without specific activation or genetic modification. This makes Streptomyces an exceptionally versatile and modifiable platform for developing new drugs.

Care4Living’s clients are primarily international pharmaceutical manufacturers. In Finland, fermentation-based drug development is rare, but globally, demand is increasing. Typically, a client purchases a microbial strain from a public collection, and Care4Living enhances it into a more efficient producer. The company also designs the full production process: fermentation, purification, and analytics.

Strain development and process optimization is time-intensive—often taking three to five years—but it's a critical part of the pharmaceutical production chain. For complex molecules, fermentation is not only more efficient but also more environmentally friendly, generating less solvent waste and hazardous byproducts.

Despite operating on a small scale and without external funding, Care4Living's technological expertise is in demand. New client relationships are initiated selectively, and the company has so far relied on minimal marketing.

“We’ve grown through sales alone, without venture capital. I want to keep this a family business. But now we’re seeing rising interest in fermentation-based production—especially as Europe and the U.S. talk about reshoring pharmaceutical manufacturing from Asia.”

Care4Living exemplifies Finnish biotech expertise, combining deep specialization, long-term experience, and international trust. The company is known among its clients as a reliable and highly skilled partner—and Finnish origins are held in high regard in the industry.